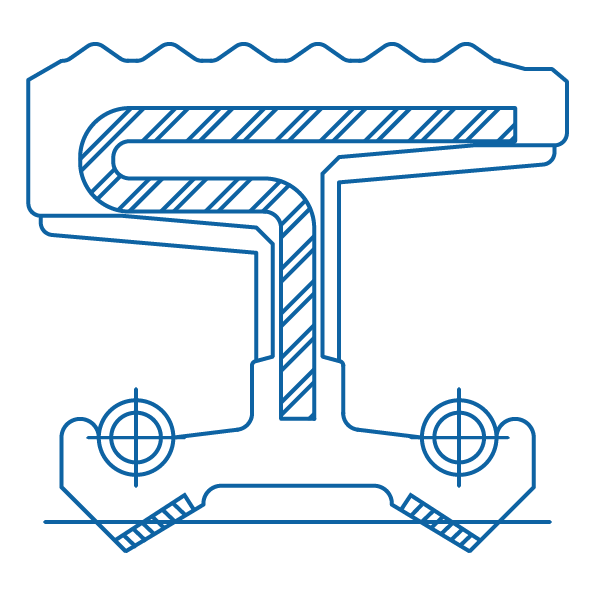

Type DUO Oil Seals

DUO-type seals according to DIN 3760 are designed with two active sealing lips, both in contact with the shaft, allowing for dual sealing functionality in opposite directions. This configuration is ideal for applications requiring the containment of two different fluids (such as oil and grease) or where effective separation between the internal and external environments is necessary without compromising performance.

Unlike conventional seals with a passive dust lip, DUO seals feature two dynamic sealing lips, each actively sealing against the shaft. Depending on the model, these lips may include reinforcing springs or not. This configuration enables the seal to function effectively in systems with pressure differentials on either side of the shaft or where there is a risk of cross-contamination between compartments.

The design may feature a fully metallic structure or an elastomer-coated outer surface, allowing adaptation to various housings—from high-precision metal casings to rougher surfaces. Some DUO models also incorporate intermediate retention chambers to enhance fluid separation performance.

They are widely used in engines, gearboxes, compressors, pumps, and complex industrial machinery where a robust, durable, and effective bidirectional sealing solution is required. The most common materials include NBR, HNBR, and FKM, selected based on the type of fluids, operating temperature, and working conditions.

For more details about DUO seals and their suitability for your specific application, please consult our technical data sheets or contact our team via the inquiry form on our website. CONTACT. Our technical team will advise you on the best solution for your application.

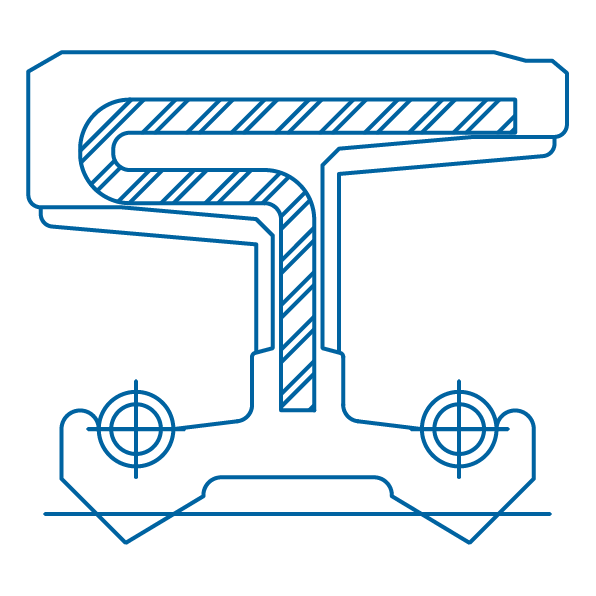

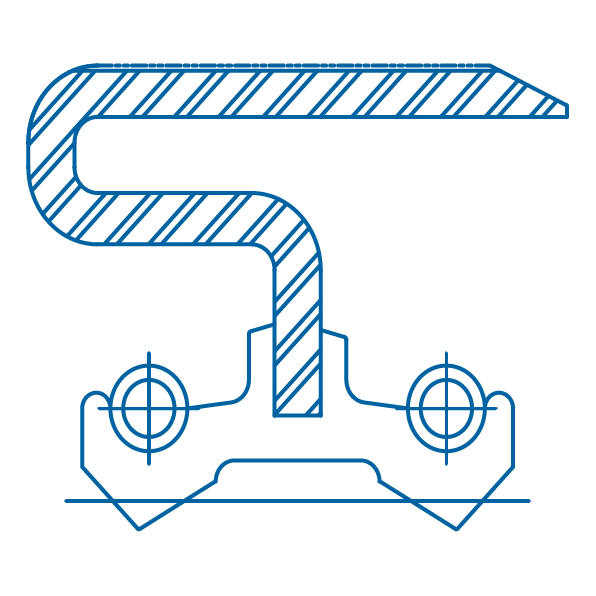

DB

DIN 3760 BDUO

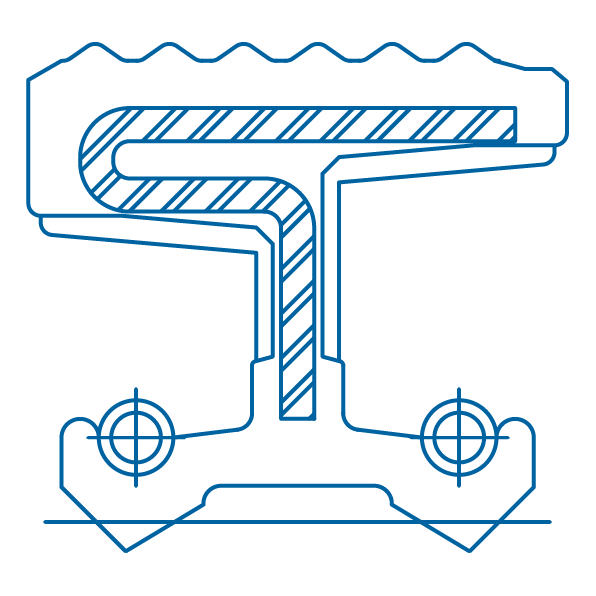

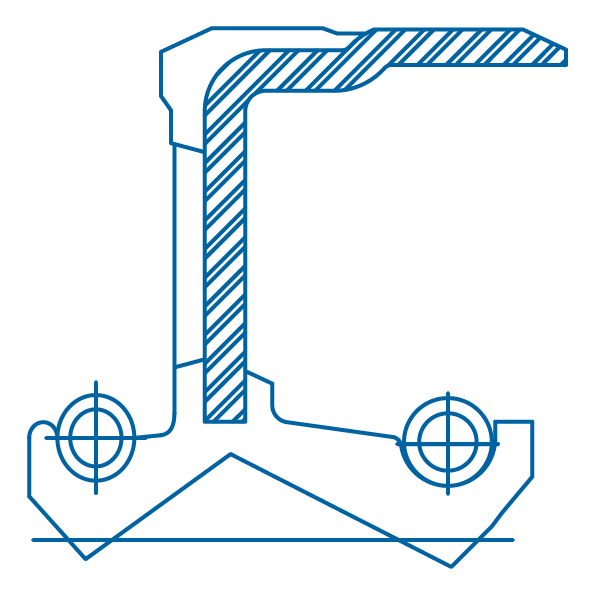

DBC

Partial rubber coating

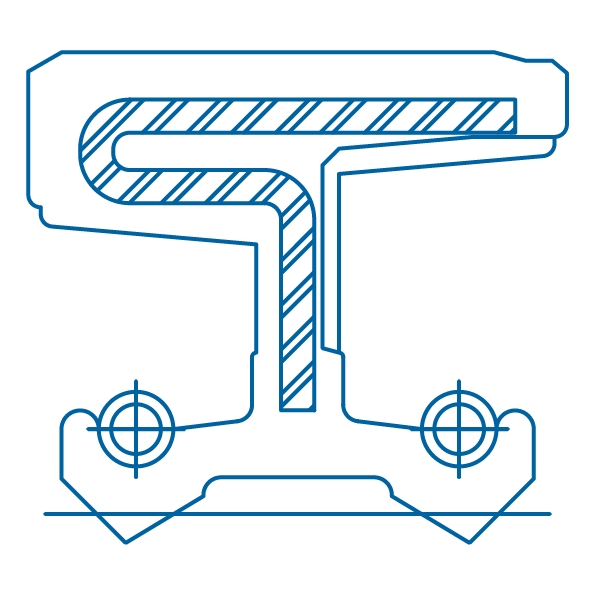

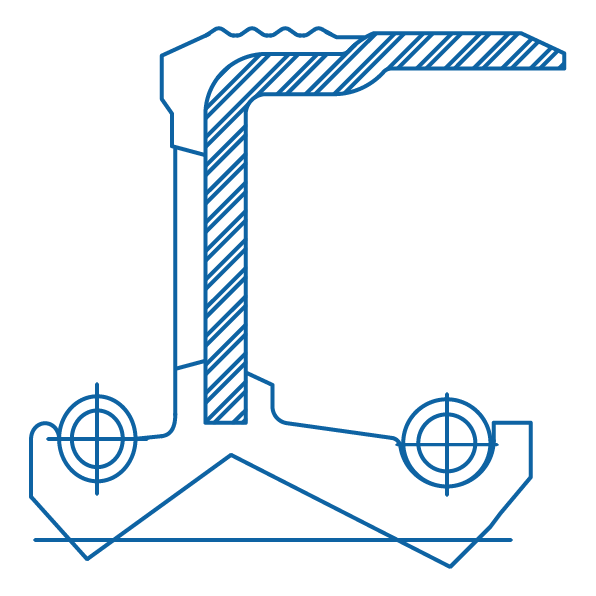

DBG

Partially grooved rubber coating

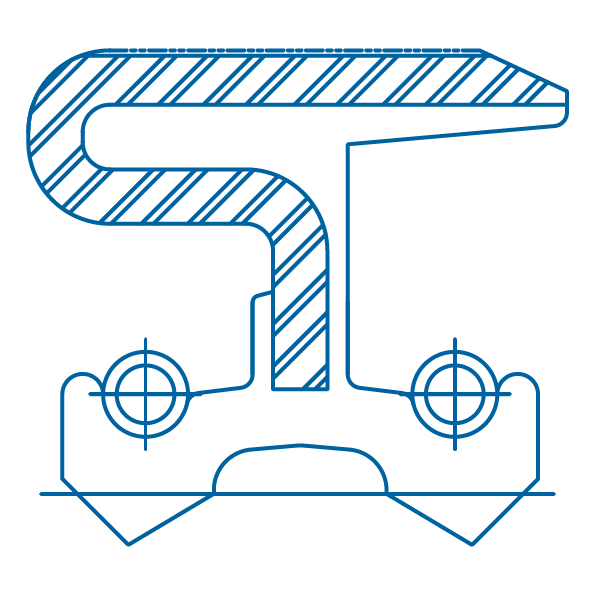

DM

Inner coating

DG-PL

PTFE REINFORCEMENT

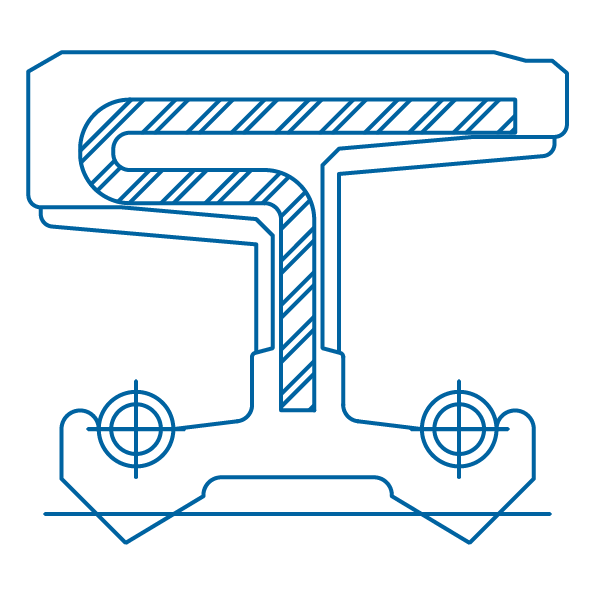

DA

DIN 376O CDUO