Type COMBI Oil Seals

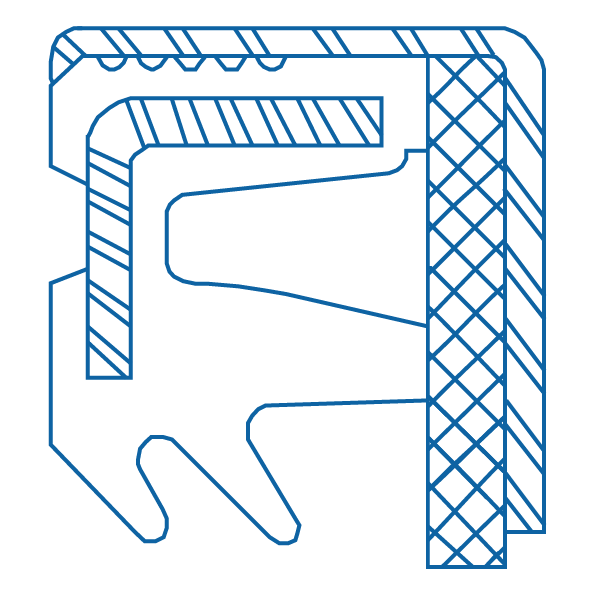

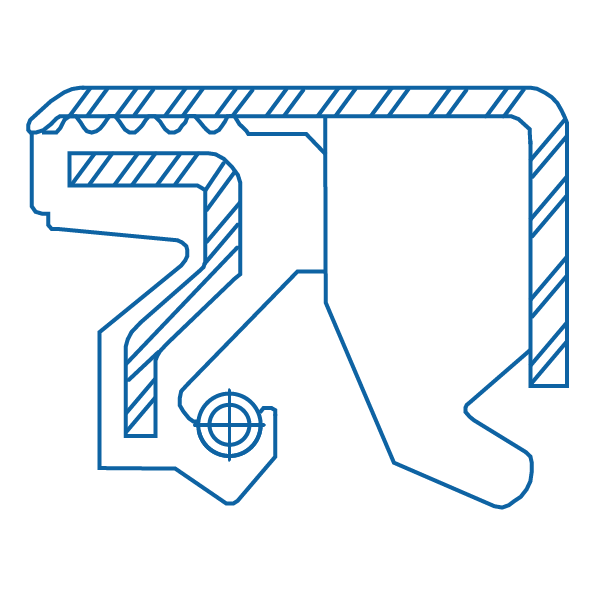

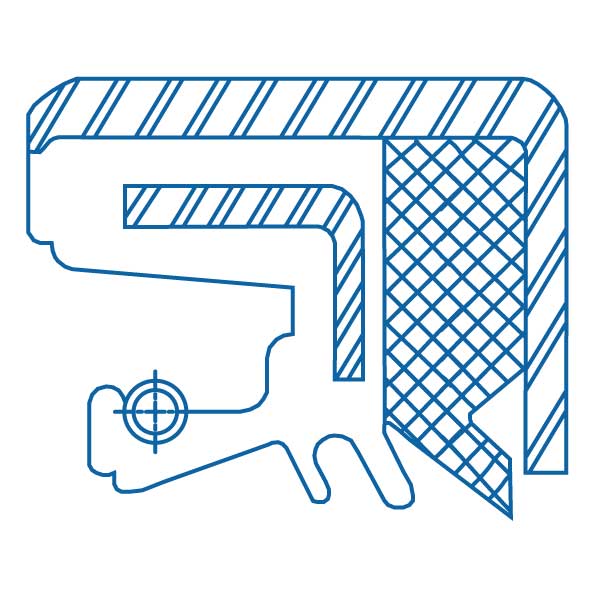

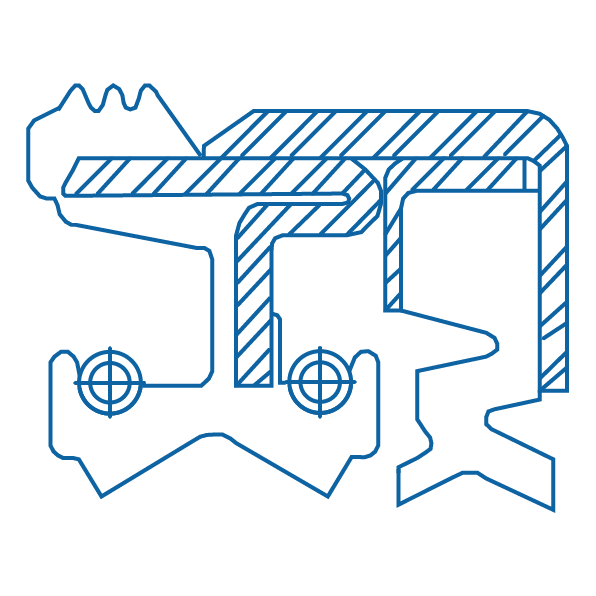

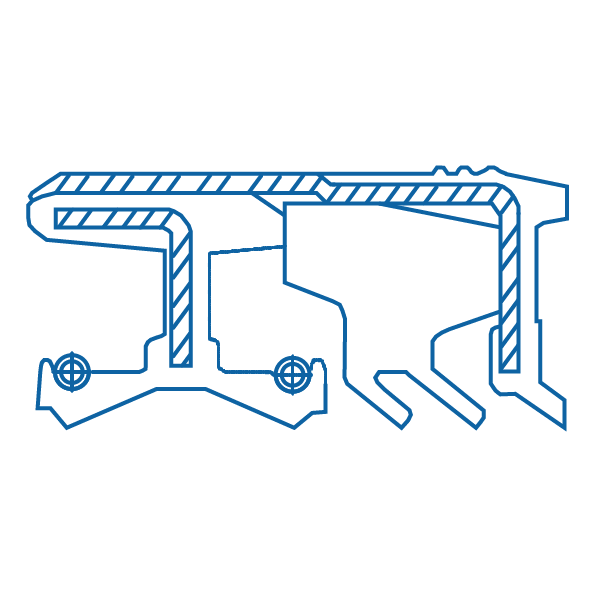

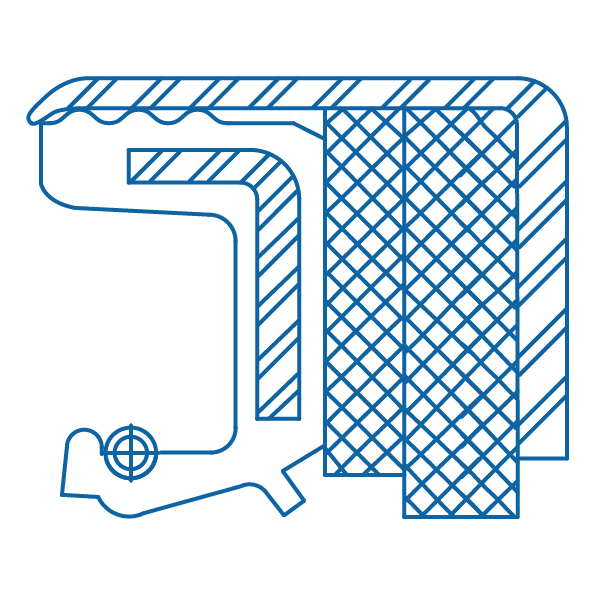

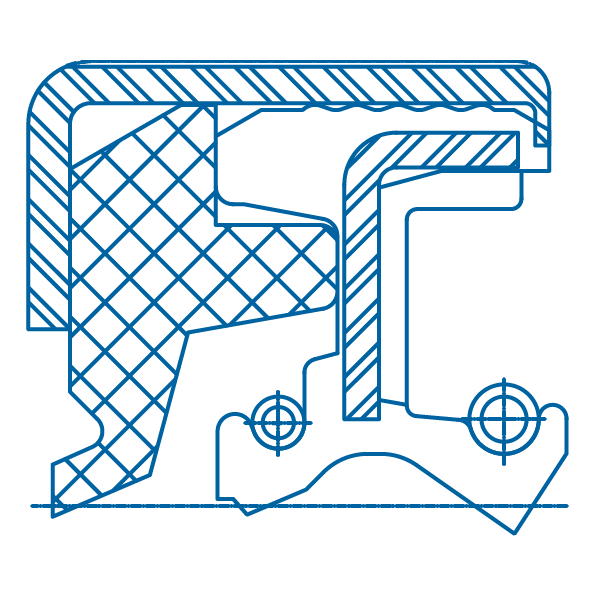

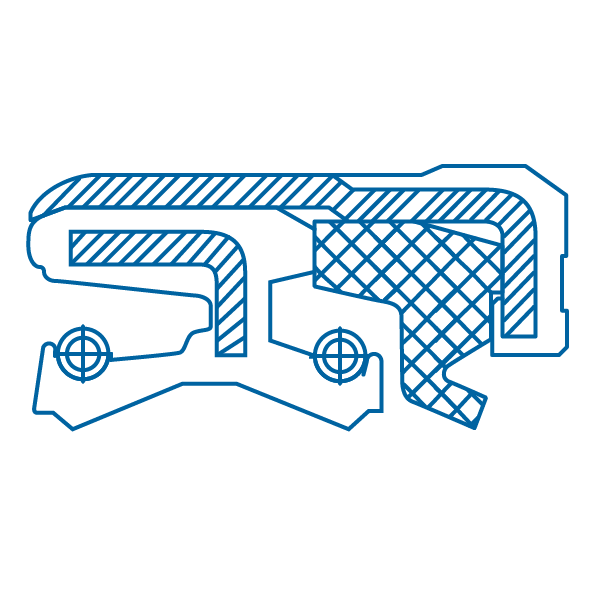

COMBI-type shaft seals are high-performance sealing solutions, specifically designed for harsh environments with heavy exposure to dust, mud, moisture, or abrasive particles. Their key feature is the integration of a conventional radial shaft seal with an additional scraper or reinforced dust lip, which acts as an active barrier against external contaminants. Unlike a standard dust lip, the additional element in COMBI seals is more robust and typically made from reinforced elastomers or polyurethane.

This hybrid design allows the main sealing lip to retain the lubricant (oil or grease) effectively, while the scraper or secondary lip prevents the ingress of dirt, water, or other debris—even under dynamic conditions or during temporary immersion. COMBI seals are especially valuable in applications involving rotational or reciprocating motion in contaminated environments, where extending the service life of both the seal and shaft is critical.

COMBI oil seal may include a metal outer shell or an elastomer-coated exterior, depending on housing requirements. Multiple variants are available, with one or more scraper lips, depending on the required level of protection. They are commonly manufactured from NBR, HNBR, FKM, or polyurethane (PU), selected based on operating temperature, fluid compatibility, and environmental abrasiveness.

They are widely used in wheel hubs, agricultural drivetrains, construction equipment, off-road vehicles, forestry machinery, and industrial systems, where durability, resistance to contamination, and reliable sealing performance are essential.

For more details about COMBI seals and their suitability for your specific application, please consult our technical data sheets or contact our team via the inquiry form on our website. CONTACT. Our technical team will advise you on the best solution for your application.