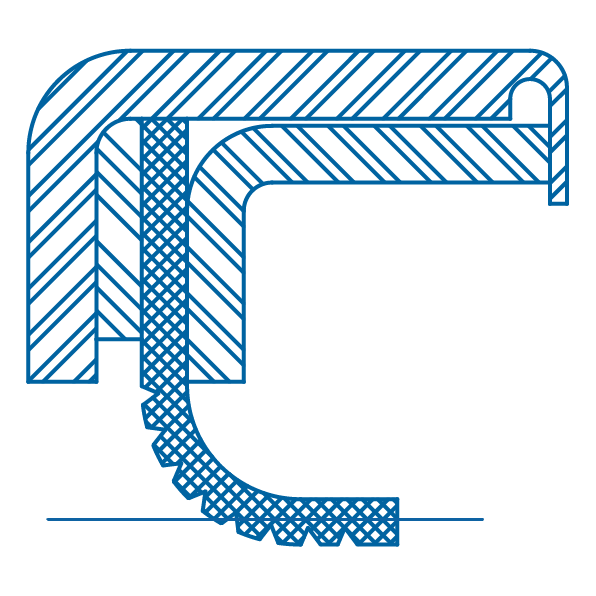

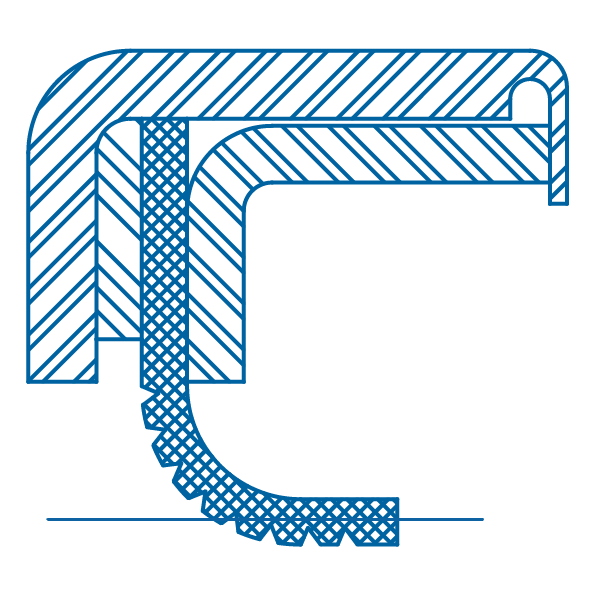

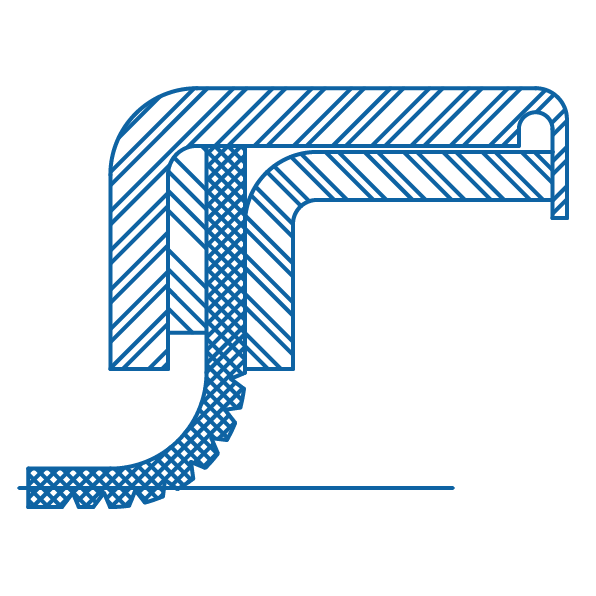

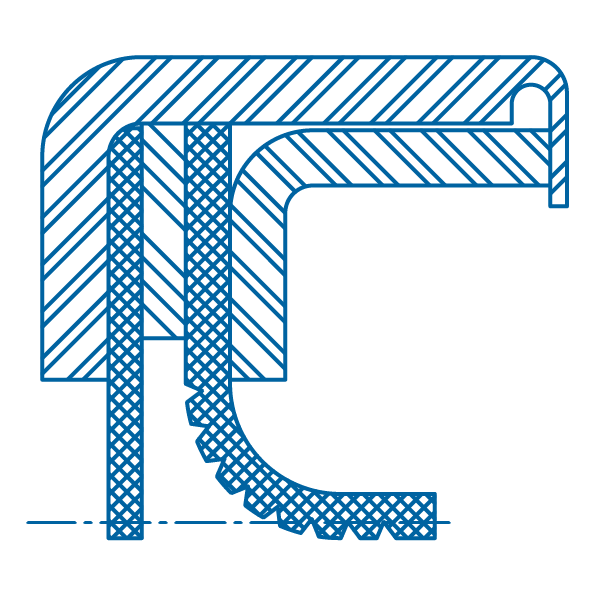

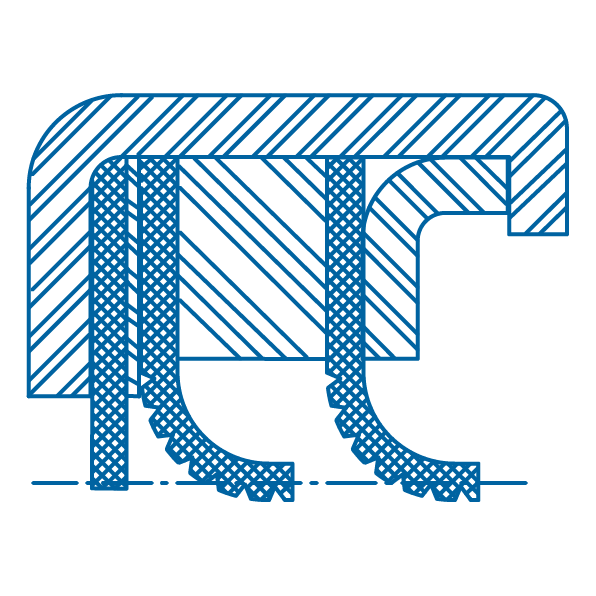

Type LT Oil Seals

PTFE lip seals are specially developed for applications that require a perfect balance between low friction, chemical resistance, and reliability at high speeds and temperatures. Thanks to the properties of Teflon, these seals provide efficient sealing even under extreme operating conditions, enhancing equipment efficiency without compromising durability.

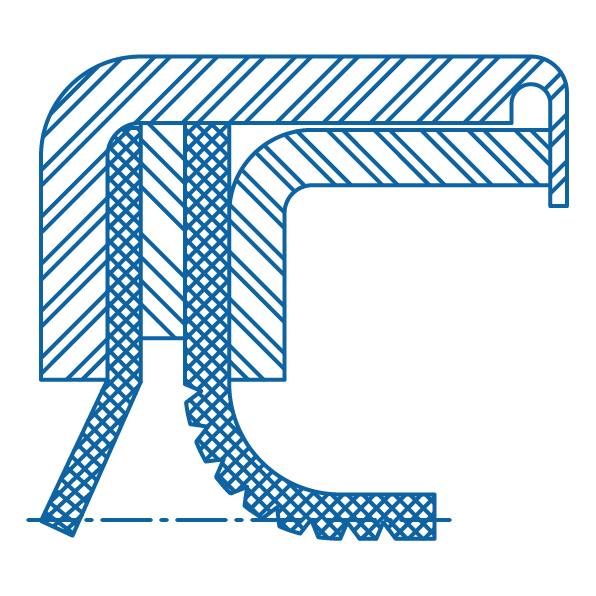

The PTFE lip features an optimized geometry that minimizes contact pressure on the shaft, significantly reducing friction, breakaway torque, and wear. This results in lower heat generation, more efficient energy consumption, and an extended service life for both the seal and the associated components. Despite its low coefficient of friction, the design maintains excellent lubricant retention and acts as a reliable barrier against the ingress of contaminants, thus preserving the integrity of the systems in which it is installed.

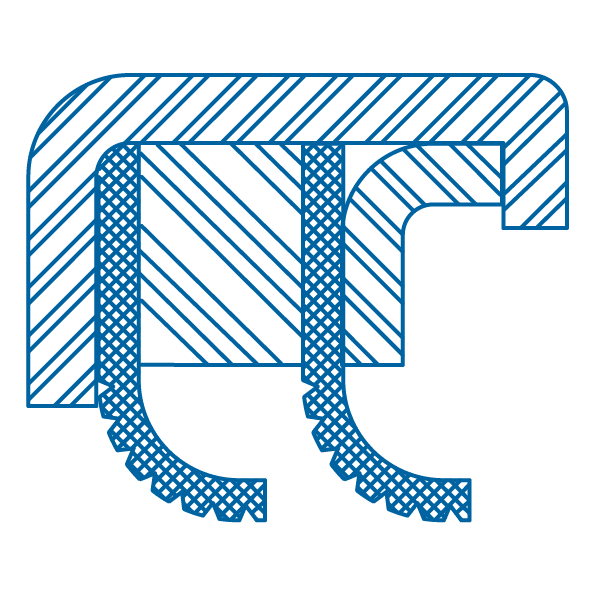

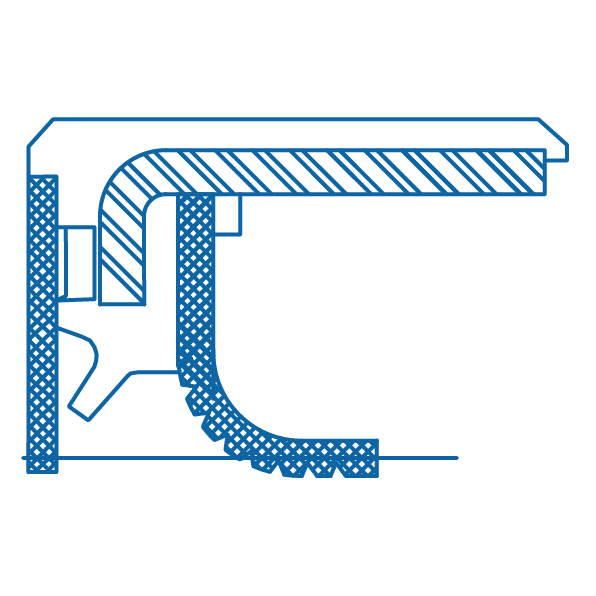

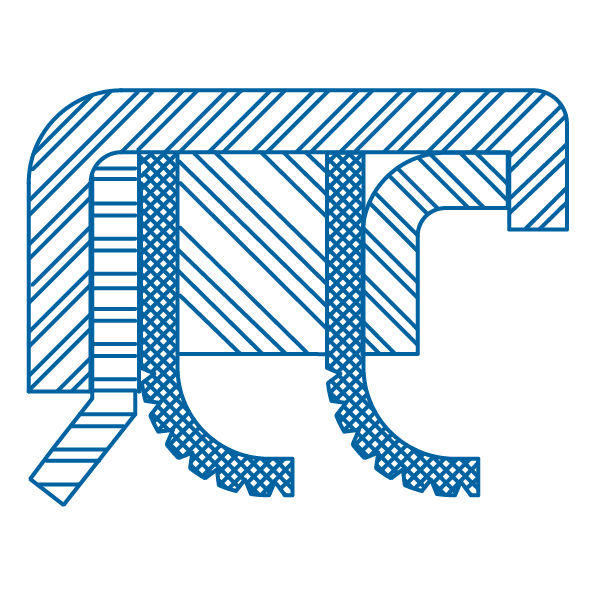

These seals can be manufactured with one or multiple sealing and dust lips, with or without a garter spring, depending on the level of sealing required by the application. Their bodies can be metallic, elastomer-coated, or hybrid, while the PTFE lip can be virgin or filled with special fibers that improve its mechanical properties and make it compatible with a wide range of lubricants, hydrocarbons, and aggressive chemical environments. In some designs, it is combined with elastomers such as NBR or FKM to optimize static sealing in the housing.

PTFE seals are commonly used in high‑efficiency electric motors and servomotors, precision gearboxes and reducers, high‑speed pumps and compressors, turbochargers, and hybrid or electric systems, as well as in industrial machinery operating in environments with extreme temperatures or chemical exposure. Their ability to reduce friction without compromising sealing performance makes them a key component for improving overall equipment performance and increasing operational reliability.

For detailed information on available configurations and to receive technical advice on the most suitable solution for your specific application, we recommend consulting our technical datasheets or contacting our specialized team through the contact form. CONTACT.