Type LX Oil Seals

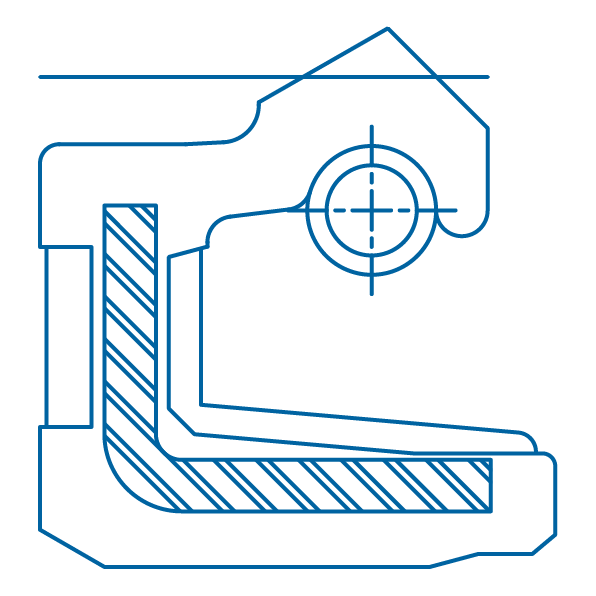

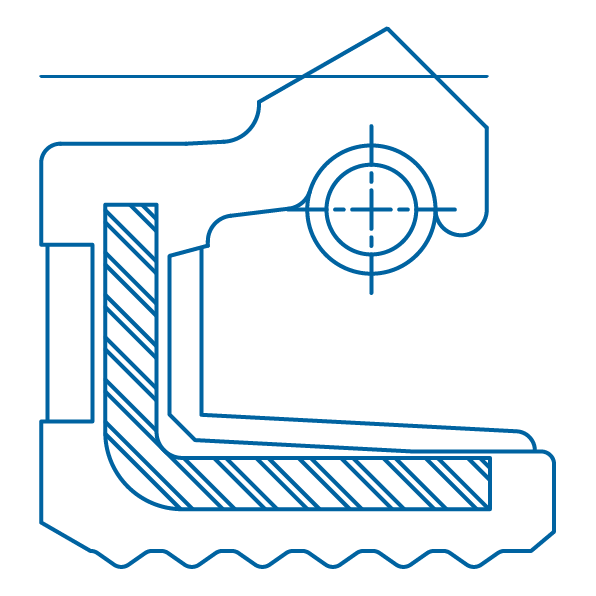

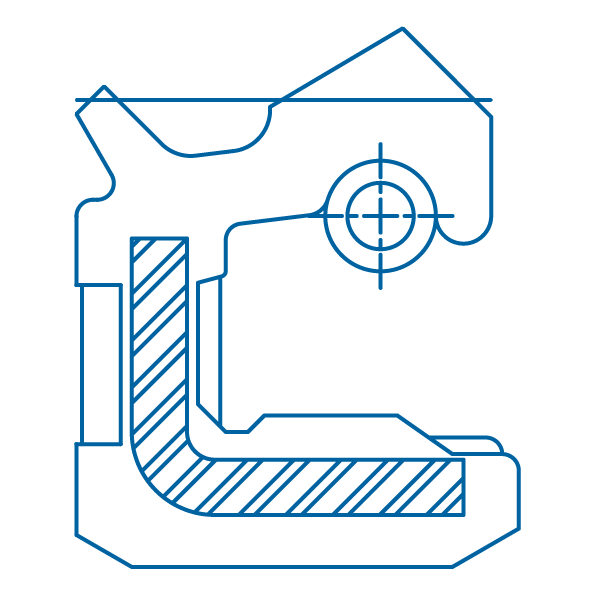

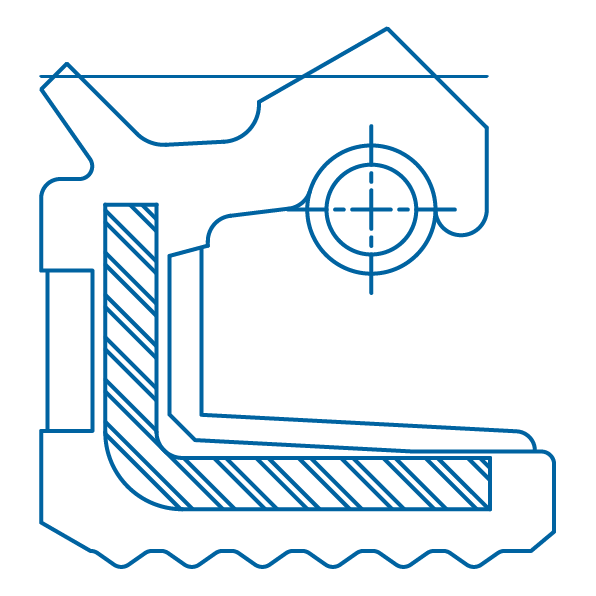

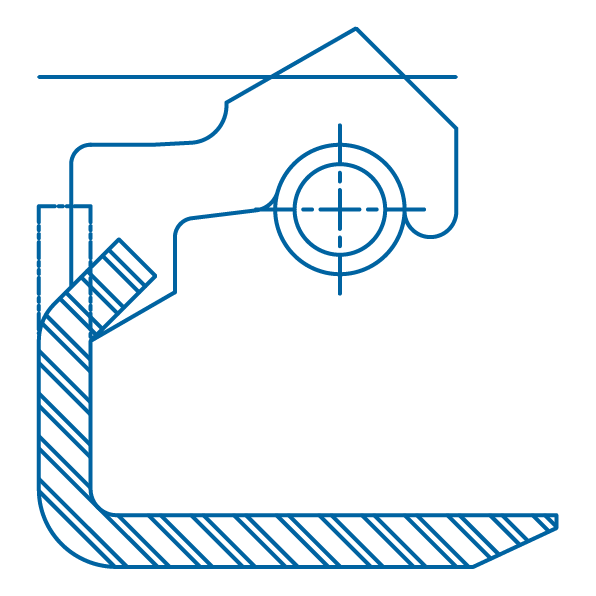

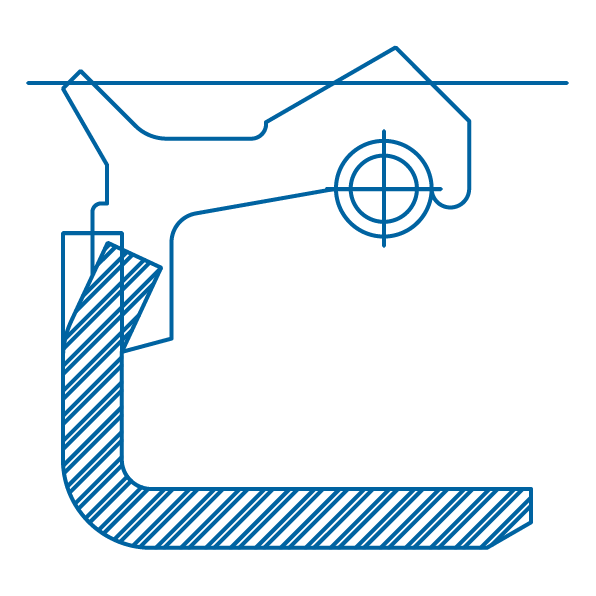

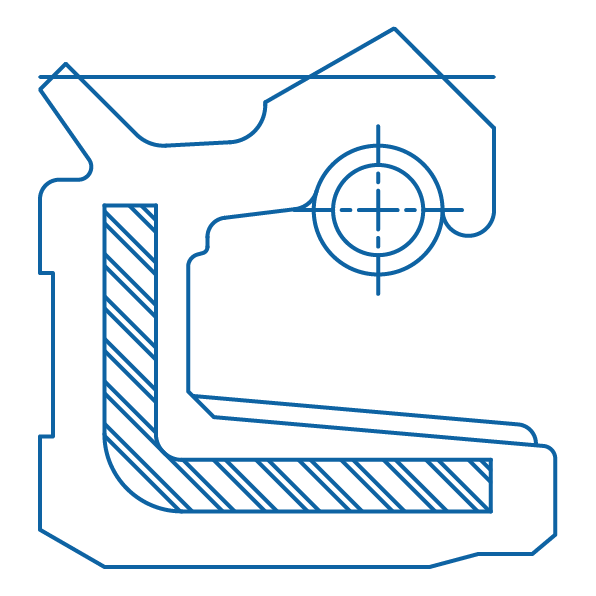

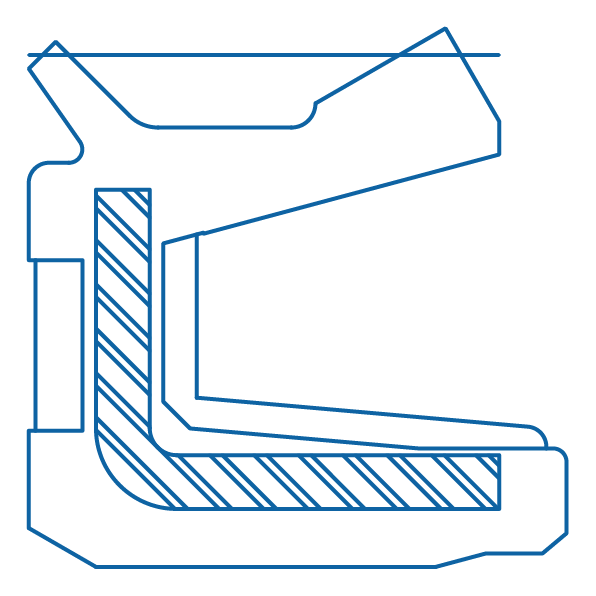

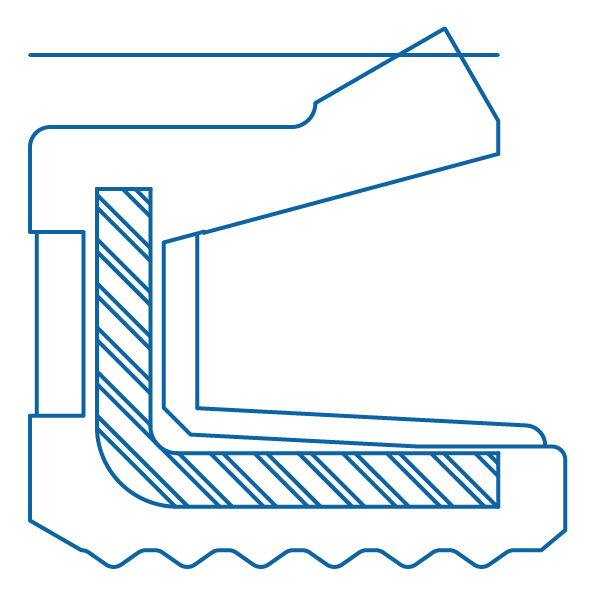

LX-type external sealing seals are designed for applications where sealing is performed towards the outside of the housing, providing a robust and reliable solution under demanding operating conditions. These seals combine a metal casing, with or without elastomer coating, and sealing lips that may include a garter spring and even additional dust lips. Their inverted sealing design positions the primary lip on the outside, optimizing protection against leakage, environmental exposure, and the ingress of contaminants.

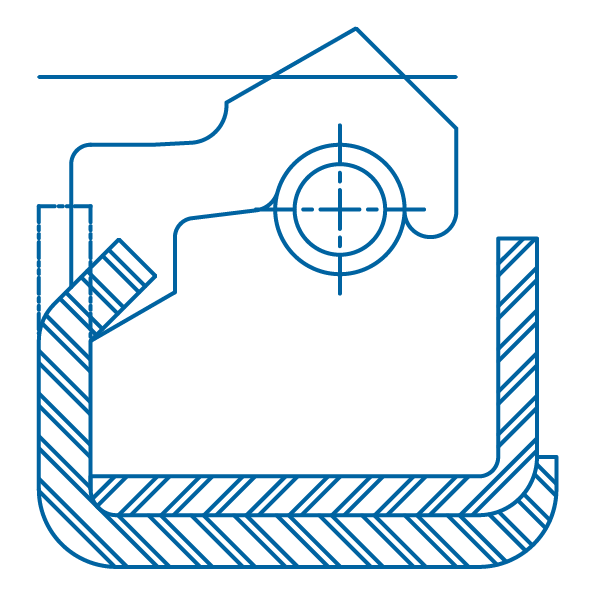

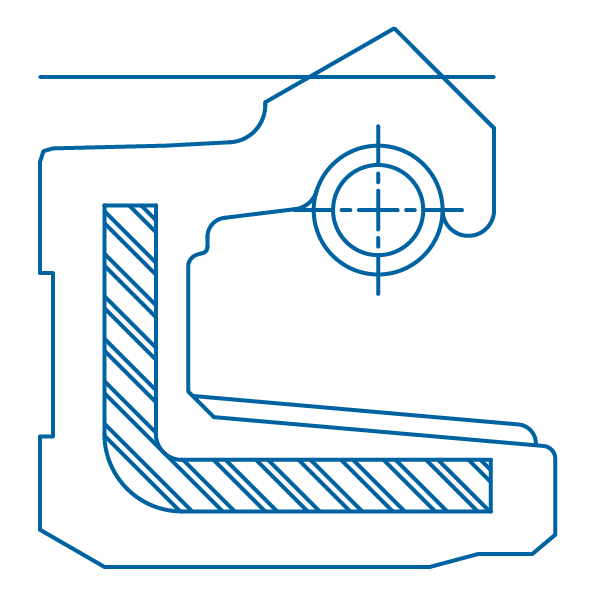

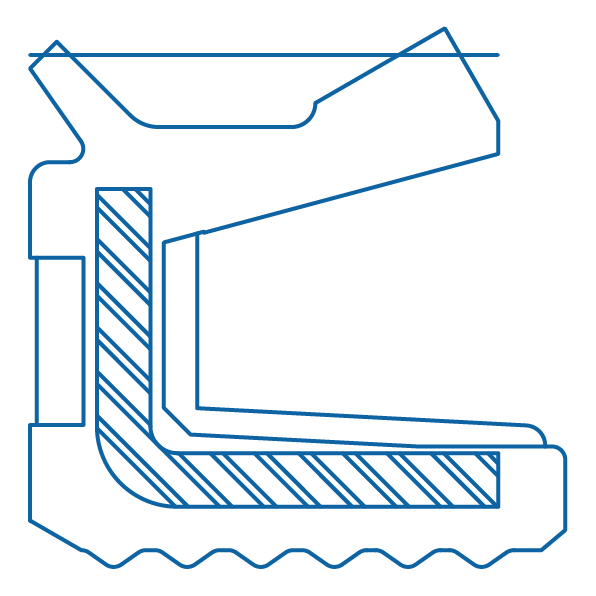

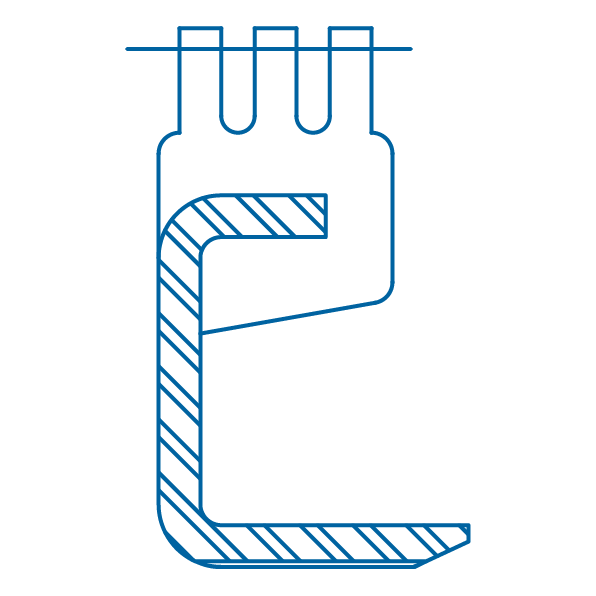

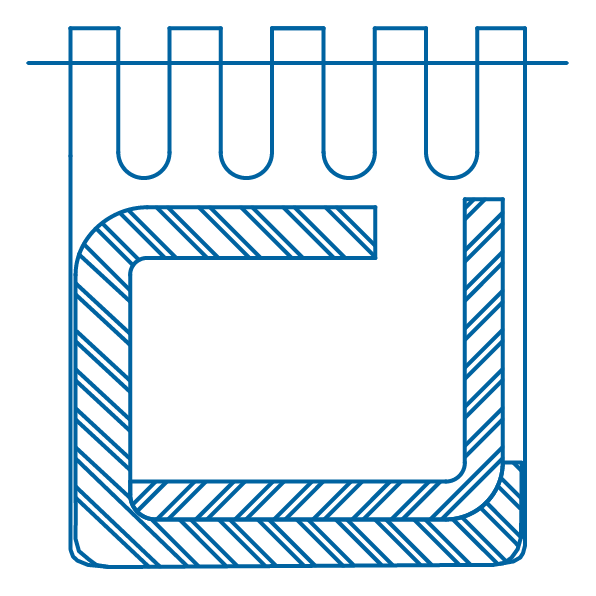

The geometry of the sealing lip has been engineered to generate low radial forces and minimize wear, while ensuring excellent lubricant retention and effective sealing of both low and high viscosity fluids. Depending on the configuration, these seals can incorporate one or several active and dust lips, grooved inner surfaces to facilitate assembly, reinforced rubber coatings to prevent corrosion, and additional metal cages that provide greater rigidity and stability, particularly for large diameters.

Their construction allows for thermal expansion compensation, tolerance of housings with higher surface roughness, and a reduced risk of corrosion in the assembly. Thanks to these features, LX-type seals are suitable for a wide range of industrial applications, including electric motors, gearboxes, precision reducers, pumps, compressors, turbochargers, hybrid and electric systems, and machinery operating in demanding environments with dust, moisture, or chemical exposure.

Manufactured from elastomers such as NBR, FKM, HNBR, EPDM, ACM, or VMQ, and combined with metal cages in carbon steel or stainless steel AISI 304 and 316, LX seals deliver durability and long-term reliability. Profiles with full or reinforced elastomer coating provide superior static sealing, while variants with single or double metal cages ensure greater stability under dynamic conditions. This versatility allows the selection of the most suitable configuration for each application, optimizing equipment service life and reducing maintenance interventions.

For guidance on selecting the most appropriate LX model and for detailed recommendations on assembly, tolerances, and materials, please refer to our technical datasheets or contact our specialized team through the contact form CONTACT.